Tungsten Carbide strics cutter maka osisi

Nkowa

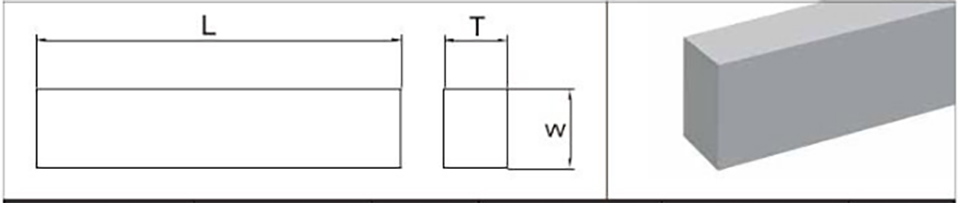

A na-emekarị ihe mgbochi dị larịị na wolfram carbide na pobelligs usoro Metallurgy ntụ ntụ. Usoro mmepụta nke Tungsten Carbide Barcus bụ por fig, bọlbụ igwe, na-asụ ma na-ama jijiji. Maka iji dị iche iche, ọdịnaya nke WC na CO na Tungsten Carbide Square abụghị otu. A na-ejikarị ụlọ ọrụ carbinger dị elu na-acha aja aja, ihe eji eme ya, ihe eji eme ya, pcB, wdg, wdg carbide stamlọ ọrụ ma ọ bụ ebe omumu, na-ata ahụhụ.

Ngwa

1. A na-eji ngwaọrụ na-eguzogide ọgwụ. Dị ka mma ụlọ ọrụ ụlọ ọrụ, mma na-akụ gwepu, wdg.

2 Dị ka ụgbọ okporo ígwè nke igwe ngwaọrụ, mgbochi Ivolution prate nke igwe igwe ATM, wdg.

3

4. A na-emebu ebu.

5. Ihe Njirimara nke ihe eji eme ihe eji eme ihe eji eme ihe di iche iche edoghi anya, na ihe kwesiri ekwesi kwesiri ka ahota ya dika eji eme ya.

Nkowa

A na-ahụkarị dị n'okpuru:

| Okpurukpu | Mgbasa | Ogologo | Okpurukpu | Mgbasa | Ogologo | ||||

| mm | mm Ndidi | mm | mm Ndidi | + 1.5mm Ndidi | mm | mm Ndidi | mm | mm Ndidi | + 1.5mm Ndidi |

| 2 | + 0.3 / 0.1 | 3 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 15 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 4 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 16 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 5 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 18 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 6 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 20 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 8 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 22 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 10 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 25 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 12 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 28 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 14 | + 0.4 / + 0.2 | 310 | 3 | + 0.3 / 0.1 | 31 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 15 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 5 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 16 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 6 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 18 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 8 | + 0.6 / + 0.2 | 310 |

| 2 | + 0.3 / 0.1 | 19 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 10 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 3 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 12 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 4 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 13 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 5 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 15 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 6 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 16 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 8 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 18 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 9 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 20 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 10 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 22 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 11 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 25 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 12 | + 0.4 / + 0.2 | 310 | 4 | + 0.3 / 0.1 | 30 | + 0.6 / + 0.2 | 310 |

| 3 | + 0.3 / 0.1 | 13 | + 0.4 / + 0.2 | 310 | |||||

Uru

Anyị na-achọta uru dị ukwuu:

1. Ike gwụrụ okpomoku.

2. Ngbanwe mgbochi na oke okpomọkụ.

3. Ezigbo ọkụ oyi na-eguzogide.

4. Ọnọdụ ọkụ.

5

6. Ike mgbochi corri-corrosion na oke okpomọkụ.

7. Ezigbo nguzogide site na kemịkal.

8. Njirimara dị elu.

9. Oge Onyinye Niile.

Ngwugwu

Ngwugwu nke ogwe osisi carbideted:

Ọ bụrụ na ị nwere ajụjụ ọ bụla, nnabata ịkpọtụrụ anyị n'oge ọ bụla.

Akụrụngwa mmepụta

Mgbochi mmiri

Fesa ihicha

Nke edere ede

TPA Press

Ọkara pịa

Hip beating

Akụrụngwa nhazi

Nko

Ibelata waya

Vetikal na-egweri

Iri na-egweri

Ụgbọ elu na-egweri

Ngwaọrụ CNC

Ngwa nyocha

Mita siri ike

Platumeta

Ihe eji eme ihe

Pobllk ngwa

Microsographic microscope