Tounsten Carbide Sheical

Nkowa

A na-ejikarị ezé silhet silherical silhey na-eji ọtụtụ ebe niile na snow ndị na-egwu mmiri na-eme ka ọ na-awụda mmanụ na snow. Na mgbakwunye, a na-ejikwa ezé bọọlụ carbide na-eji nke ọma na igwe na-egbutu ihe na igwe na-egwuri egwu, ndozi okporo ụzọ na ngwaọrụ ndị na-egwu egwu. Ezé ciment Carbide na-eji na mines na-ejikarị ihe eji eme ihe, na-egwuputa ihe na ụlọ ndị obodo.

Akwukwo icho oru

A na-eji bọtịnụ ciment carbide na-eji ebe niile na mmanụ na-awụfu ahịhịa, na-ewepu ihe ma ọ bụ akụrụngwa ndị ọzọ n'ihi akụrụngwa ha pụrụ iche. Dabere na igwe ndị dị iche iche, dị ka cone bits, ngwaọrụ igwu ala, cimeral carbide na-ekewa ụzọ dị iche iche: ọnọdụ dị iche iche, P-Mkpụrụ Z-Mkpụrụ. A na-ejikarị teknụzụ dị elu dị elu nke ngwaahịa anyị, a na-ejikarị ezé na-eme mkpọtụ dị ka ihe eji eme ya, ihe eji eme igwe na ngwa ngwa maka snow na nhicha okporo ụzọ. A na-ejikwa ezé bọọlụ cimet dị ka ngwaọrụ gwuo egbugbere ihe, na-egwuputa egwu, igwu mmiri na ụlọ obodo. Na mgbakwunye, a na-eji ya dị ka ihe dabara adaba maka oke egwu egwu ma ọ bụ ngwaọrụ egwuregwu olulu dabara adaba.

EGO

Cartived Carbide bụ ihe kachasị mma iji mepụta ezé bọọlụ ciment nke na-ejikarị ụlọ ọrụ na-egwu egwu.

A na-eji bọtịnụ Carbide na-eji ọtụtụ ihe na-egwuputa ihe n'ọtụtụ, na-egbu egbu ma na-ehicha n'ihi isi ike ha. A nwekwara ike iji ha na nnukwu igwe.

Greedi

| Greedi | Keujug / cm3 | WRS MPA | KemmesoHra | Akwukwo icho oru |

| Cr4c | 15.10 | 1800 | 90.0 | Eji tumadi iji belata ihe ndi ozo siri ike. |

| Nka | 14.95 | 1900 | 90.5 | Ejiri dị ka eletrik na-ejikọ, unyi, petrolem cots na scrack Balk-ezé. |

| Cribe | 14.80 | 2200 | 89.5 | Ejiri dị ka ihe dị ka isi, ọkụ eletrik, unyi, mmanụ mmanụ na-eme mkpọtụ ma na-arị elu. |

| Cr8c | 14.80 | 7.0000 | 88.5 | Tumadi ejiri mee ihe dị ka bọọlụ nke eze na obere mmetụta na-emetụta ma dị ka ịmịcha ọhịa nke Rotary Internary Mund. |

| Cr11c | 14.40 | 2700 | 86.5 | A na-ejikarị ọtụtụ ihe na-emetụta ihe na-eme ka ịkpụgharị ezé nke ihe siri ike. |

| Cr13c | 14.2 | 2850 | 86.5 | eji tumadi iji belata ezé bọọlụ na ihe siri ike na-agagharị na njedebe ntụgharị. |

| Cr15c | 14.0 | 3000 | 85.5 | Ejiri maka ijikọ mmanụ na ọkara na ọkara na-egbukepụ ngwa ngwa. |

Saiz

A na-anabata OEM.

Olu nke Turniten Carbide bọtịnụ dị ka n'okpuru:

| Udi | Akụkụ (mm) | ||||||||

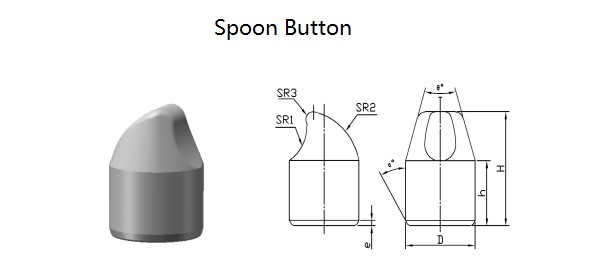

| D | H | h | Ɵ Celsius | Sr1 | Sr2 | Sr3 | α Celsius | e | |

| S1015 | 10.25 | 15 | 9.8 | 50 | 12 | 20 | 3 | 18 | 1.2 |

| S1116 | 11.3 | 16.5 | 10.2 | 50 | 15 | 24 | 3 | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2.5 | 18 | 1.5 |

| S1319 | 13.35 | 19 | 12 | 50 | 15 | 20 | 3 | 18 | 1.5 |

| S1421 | 14.35 | 21 | 12.5 | 40 | 12 | 25 | 3 | 18 | 1.8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | 3 | 18 | 1.8 |

| S162 | 16.35 | 24 | 13 | 30 | 15 | 20 | 3 | 18 | 2 |

| S1827 | 18.25 | 27 | 14.5 | 30 | 18 | 20 | 3 | 18 | 2 |

| Udi | Akụkụ (mm) | |||||||

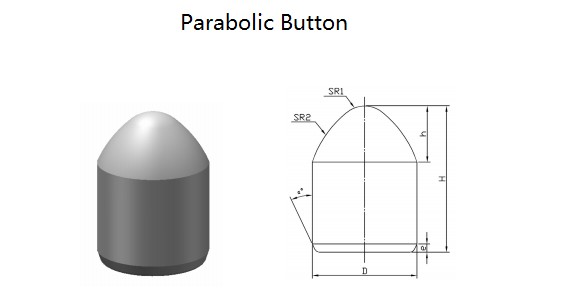

| D | H | Sr1 | Sr2 | h | α Celsius | β Celsius | e | |

| D0711 | 7.25 | 11 | 1.9 | 8.7 | 3.9 | 20 | 25 | 1.6 |

| D0812 | 8.25 | 12 | 2.5 | 9 | 4.5 | 20 | 25 | 1.6 |

| D0913 | 9.25 | 13 | 2.5 | 11 | 5. | 20 | 25 | 1.8 |

| D1015 | 10.25 | 15 | 3.2 | 11.8 | 5. | 20 | 25 | 1.8 |

| D1117 | 11.3 | 17 | 3 | 13.5 | 6 | 20 | 25 | 1.8 |

| D1218 | 12.35 | 18 | 3 | 12 | 6.5 | 20 | 20 | 2 |

| D1319 | 13.35 | 19 | 3.5 | 13.5 | 7.1 | 20 | 20 | 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | 2 |

| Udi | Akụkụ (mm) | ||||||

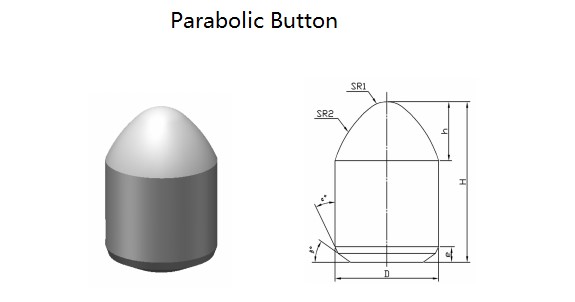

| D | H | Sr1 | Sr2 | h | α Celsius | e | |

| D0711A | 7.25 | 11.0 | 1.9 | 8.7 | 3.9 | 18 | 1 |

| D081A | 8.25 | 12.0 | 2.5 | 9 | 4.5 | 18 | 1 |

| D091A | 9.25 | 13.0 | 2.5 | 11 | 5. | 18 | 1 |

| D1015a | 10.25 | 15.0 | 3.2 | 11.8 | 5. | 18 | 1.2 |

| D111A | 11.3 | 17.0 | 3 | 13.5 | 6 | 18 | 1.2 |

| D121a | 12.35 | 18.0 | 3 | 12 | 6.5 | 18 | 1.5 |

| D131a | 13.35 | 19.0 | 3.5 | 13.5 | 7.1 | 18 | 1.5 |

| D1420a | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

| Udi | Akụkụ (mm) | |||||

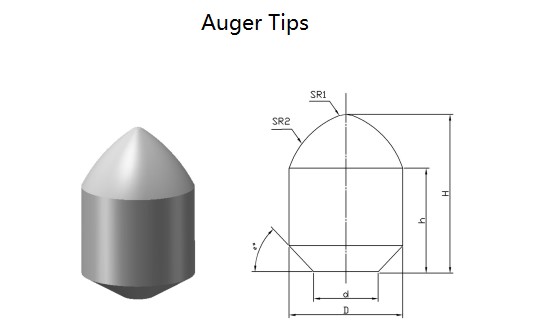

| D | d | H | h | Sr1 | Sr2 | |

| JM1222 | 12 | 3.0 | 22 | 15 | 1.5 | 26 |

| JM145 | 14 | 4.0 | 25 | 17 | 1.5 | 26 |

| JM1625 | 16 | 5.0 | 25 | 16 | 1.5 | 26 |

| JM1828 | 18 | 5.0 | 28 | 18 | 1.5 | 26 |

| JM2428 | 24 | 10.1 | 28 | 16 | 2 | 36 |

| JM2534 | 25 | 18.0 | 34 | 20 | - | 25 |

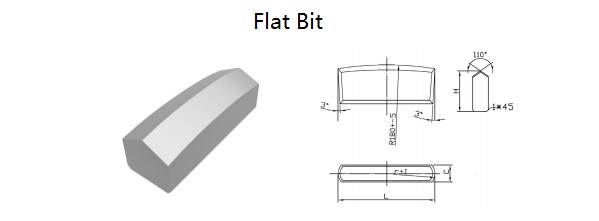

| Udi | Akụkụ (mm) | |||||

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12.5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12.5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12.5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12.5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12.5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12.5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12.5 | 10 | 19 |

| K040 | 40 | 18.0 | 15 | 12.5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12.5 | 10 | 21 |

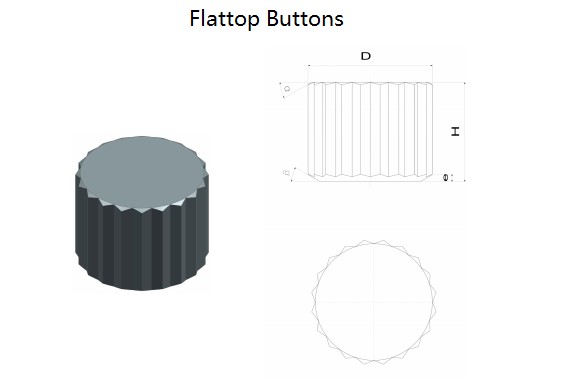

| Udi | Akụkụ (mm) | ||||

| D | H | t | α Celsius | e | |

| Mh0806 | 8 | 6.0 | 0.5 | 25 | 1.1 |

| Mh1008 | 10 | 8.-8 | 0.5 | 25 | 1.9 |

| Mh1206 | 12 | 6.0 | 0.5 | 25 | 1.9 |

| Mh1208 | 12 | 8.-8 | 0.5 | 25 | 2.5 |

| Mh1410 | 14 | 10.0 | 0.5 | 25 | 2.5 |

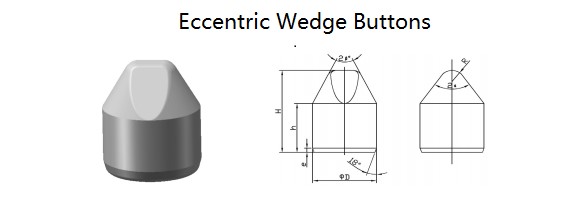

| Udi | Akụkụ (mm) | |||||||

| D | H | h | R | r | α Celsius | β Celsius | e | |

| X0810 | 8 | 10 | 6.5 | 2 | 1.8 | 45 | 22.5 | 1.5 |

| X1011 | 10 | 11 | 7 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1013 | 10 | 13 | 9 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2.5 | 22.5 | 22.5 | 1.5 |

| X1215 | 12 | 15 | 9 | 3 | 2.5 | 45 | 22.5 | 1.5 |

| X1217 | 12 | 17 | 10.5 | 3.5 | 3 | 35 | 20 | 1.5 |

| X1418 | 14 | 18 | 10 | 3.5 | 3 | 45 | 22.5 | 1.5 |

| X1420 | 14 | 20 | 11 | 2.7 | 3 | 35 | 22.5 | 1.5 |

| X1520 | 15 | 20 | 12 | 3 | 3 | 40 | 22.5 | 1.5 |

| X1621 | 16 | 21 | 11 | 2.6 | 3 | 35 | 22.5 | 2 |

| X1623 | 16 | 23 | 12 | 3 | 3.5 | 30 | 18 | 2 |

| X1721 | 17 | 21 | 13 | 4 | 3.5 | 40 | 22.5 | 2 |

| X1724 | 17 | 24 | 13 | 3.5 | 3.5 | 30 | 22.5 | 2 |

| X1929 | 19 | 29 | 17 | 4 | 3 | 30 | 15 | 2 |

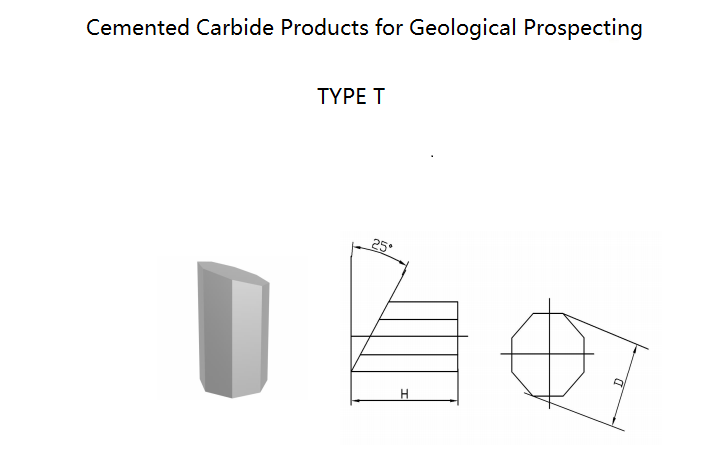

| Udi | Akụkụ (mm) | |

| D | H | |

| T105 | 5. | 10 |

| T106 | 7 | 10 |

| T107 | 7 | 15 |

| T109 | 9 | 12 |

| T110 | 10 | 16 |

Uru Anyị

Igwefoto ciment carbide nwere ike iguzogide na mmetụta mmetụta siri ike, ma nwee ọsọ dị elu karịa ngwaahịa ndị yiri ya. Ndụ na-abụghị nke bit nke bit bụ ihe dị ka ugboro 5-6 ma ọ bụrụhaala na nke ahụ nwere otu dayameta ahụ, nke bara uru ịchekwa oge ọrụ na-arụ ọrụ na-arụ ọrụ na ọsọ ọsọ.

Iji nweta nkọwa zuru ezu, na-anabata ịkpọtụrụ anyị n'oge ọ bụla.

Akụrụngwa mmepụta

Mgbochi mmiri

Fesa ihicha

Nke edere ede

TPA Press

Ọkara pịa

Hip beating

Akụrụngwa nhazi

Nko

Ibelata waya

Vetikal na-egweri

Iri na-egweri

Ụgbọ elu na-egweri

Ngwaọrụ CNC

Ngwa nyocha

Mita siri ike

Platumeta

Ihe eji eme ihe

Pobllk ngwa

Microsographic microscope