Tringsten carbide warara na-eme nke Wc Tungsten Unting forting, ihe eji eme ya, na-asụ carbing watbide watbide abụghị otu, ma iji ya rụọ ọrụ.

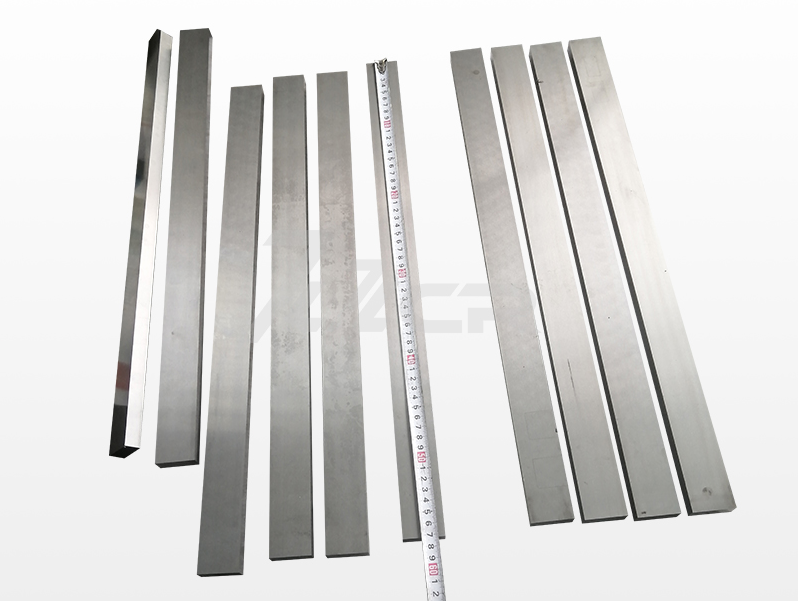

Otu n'ime ihe ndị kachasị na Tungsten Carbips, a kpọrọ ya aha na-enweghị akụkụ ya (ma ọ bụ n'ákwù), nke a makwaara dị ka tungsten Carbide warara / efere. Crump Carbide nwere ezigbo ihe siri ike, ọ na-eyi modul na-eguzogide, ike dị elu, ike dị ala, na-enwe nkụda mmụọ na eletriki yiri ígwè na alloys.

Kedu ihe kpatara nke akeozoputanke tungsten carbide mpempe? Chuangrui Carbide ga-aza ọzọ:

(1.)

(2)Keozoputaga-eme mgbe a họpụtara onye na-anya isi ma jiri ya mee ihe dịka ọmụmaatụ, a na-eji ụgbọ boyax na-arụ ọrụ nke ọma n'ihi na borax nwere ike ịmịcha nke ọma na elu ahụ, nakeozoputaphenomenon mere.

(3) Ọnọdụ ọkụ kwesịrị ekwesị kwesịrị 30 ~ 50 Celsius C karịa isi nke na-emebi emebi, nakeozoputaga-eme ma ọ bụrụ na ọnọdụ okpomọkụ dị oke ma ọ bụ dị ala. Kpo oku nke ukwuu nwere ike ibute oxhid na weld. Na-eji zinc-nwere ọla na-egwe ọka ga-enye ndị na-acha anụnụ anụnụ ma ọ bụ na-acha ọcha. Mgbe ọnọdụ ọkụ dị ala dị ala, obere Weld ga-akpụ, yana n'ime ihe mgbochi ndị a na-eme na slag. Ọnọdụ abụọ a dị n'elu ga-ebelata ike nke Weld, ọ dịkwa mfe izeld mgbe a na-atọ ụtọ ma ọ bụ jiri ya.

(4) na usoro ịmịcha, enweghị mwepu slag ma ọ bụ nke slag ma ọ bụ nke zuru oke, nke mere na nnukwu ego nke slag dị na weld, nke na-ebelata ike nke weld na-akpatakeozoputa.

Oge Post: August-28-2024