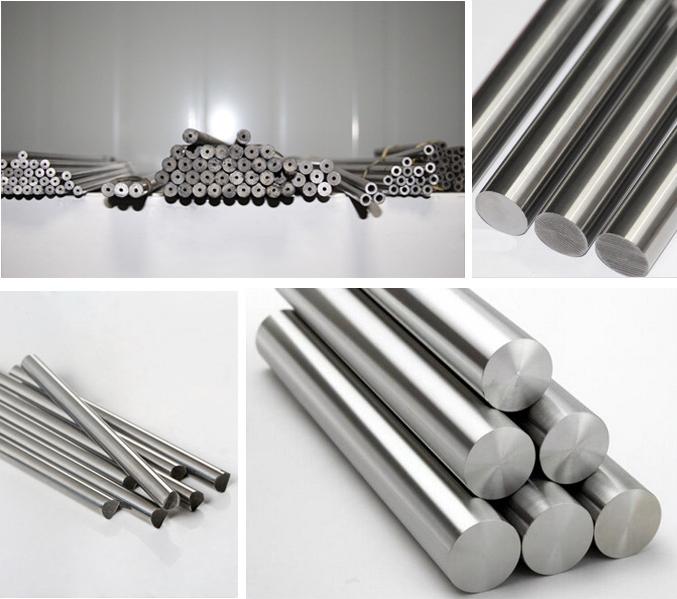

Ahịhịa carbide Rod bụ carbide gbara gburugburu mmanya, a makwaara dị ka Tungsten steel, ọ dị mfe ikwu, tungten ígwè gburugburu mmanya ma ọ bụ tungsten carbide gburugburu ụlọ mmanya. Tingsten carbide bụ ihe mejupụtara site na ntụ ntụ site na ntụ ntụ nke mejupụtara ahịhịa na-eme ihe (ngwa ngwa) na ọlakọrọ).

E nwere ụzọ abụọ na-akpụ akpụ maka mmepụta nke tungsten carbide gbara gburugburu: Otu bụ iwe, na ndọtị bụkwa ụzọ kwesịrị ekwesị iji mepụta ogige dị ogologo. Ọ nwere ike zọrọ ya ogologo ọ bụla chọrọ site na onye ọrụ ahụ n'oge a na-awụfu. Agbanyeghị, ogologo ogologo agaghị agafe 350mm. Nke ọzọ bụ ịkpụzi ntụzi aka, nke bụ ụzọ kwesịrị ekwesị iji mee ka ngwaahịa dị mkpụmkpụ. Dị ka aha ahụ na-egosi, a na-ciment carbide ntụ ntụ ka a na-abanye n'ụdị ya na ebu.

Couthed carbide nwere usoro ihe dị mma dị ka ihe siri ike, na-eyi nguzosi ike, nke na -echekwa ya na okpomọkụ nke 500 Celsius na 1000 Celsius. A na-ejikwa Carbide dị ka ihe eji eme ihe, dị ka ihe eji eme ihe, ma enwere ike iji ígwè na-egbu egbu, ma ọ bụ igwe na-egbu egbu, na-agba ngwa ngwa, ngwanrọ mangese na ihe ndị ọzọ siri ike Na-egweri (Ball Mill, ịkwa nkụ, z-mifkator ---), na-agbapụta (ọkụ dị iche iche ma ọ bụ hips ọkụ ọkụ).

Akụrụngwa ahụ bụ mmiri mmiri na-egwe mmiri, nkụ, gluu na mbelata na mbelata na nrụgide, ma mesịa na-akpụgharị na ịgha mkpụrụ.

Ọdịmma ndị a na-emepụta mmiri na-emepụta bụ na usoro nrụpụta dị ogologo. Na-apịa obere obere dayameta dị n'okpuru 3mm ma mebie njedebe abụọ ahụ ga-emebi ụfọdụ ihe. Ogologo nke carbide obere dayameta gburugburu, ka njọ nke oghere. N'ezie, nguzozi na nsogbu nwere ike imeziwanye site na cylindrical egweri na ogbo.

Ihe ọzọ bụ ịkpụzi mkpakọ, nke bụ ụzọ dị mkpirikpi ọkọlọtọ. Dị ka aha ahụ na-egosi, ọ bụ akpụ akpụ na-pịa ntụ ntụ ciment carbide na udi. Uru nke usoro ihe mgbochi nke carbide a bụ na enwere ike guzobe ya n'otu ngafe ma belata scrap. Mee ka usoro ịkpụ waya dị mfe ma kpochapụ usoro ihe akọrọ nke appsọy. Oge dị mkpụmkpụ nwere ike ichekwa ndị ahịa 7-10 ụbọchị.

N'ikwu ya hoo haa, ihe na-egosi na ị ga-eme nke ọma. Igwe nkwuwa okwu bụ ezigbo usoro maka mmepụta nke nnukwu cungsten Carbide gbara gburugburu. Site na elu Piston akàrè na nke ala, mgbapụta nrụgide a na-etinye mmiri mmiri na-ajụ oyi na roba a na-eto eto site na roba a na-enwekarị nrụgide iji mee ka ntụ ntụ ciment carbide na-eme ka ciment carbide.

Oge Post: Jan-24-2024